Architectural Plywood

Architectural Plywood is used for cosmetic surfaces, it showcases the natural beauty of wood veneer. Architectural Plywood requires a lot of attention to detail to capture the same grain consistency in veneer.

The usage for Architectural Plywood is vast, it can be used for wall panels, ceiling, columns, table-tops or any focal point to add the richness and elegance of natural wood. We can provide Architectural Plywood for any type of projects from small sets of matched panels to large scale blue-print matched jobs.

Some of the most common projects that Architectural Plywood is used in include, public buildings, professional offices, performance halls, residential cabinets as well as Jet and Yacht interiors.

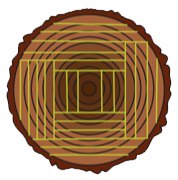

Flat Cut/Plain Sliced

*Most Common Cut

*Produces Uniform, Cathedral Grain Look

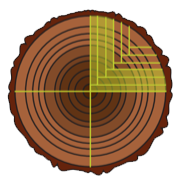

Quarter Cut

*Cut At A Wider Angle (60°-90°)

*Flecked, Straight Cut

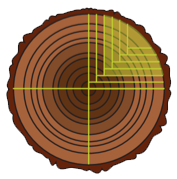

Rift Cut

*Most Expensive & Least Common Cut

*45° Angle Optimal Cut

*Combined’ Grain

*Minimized Fleck

MATCHING VENEER LEAVES WITHIN A PANEL

Running Match

Each panel face is assembled from a smany veneer leaves as necessary.

- Results in non-symmetrical appearance with some veneer leaves of unequal width.

- Often the most economical method at the expense of aesthetics.

Book Match

Veneer joints match, creating a symmetrical pattern.

- Yields maximum continuity of grain.

- Prominent characteristics will ascend or descend across the match.

- Because the tight side and loose side faces alternate in adjacent leaves, they reflect light and accept stains differently. This may yield a noticeable color variation, termed “Barber Pole.” Barber Pole is not considered a defect.

- The effect may be minimized through the use of proper finishing techniques.

Balance Match

Each panel face is assembled from veneer leaves of uniform width before edge trimming.

- Panels may contain an even or odd number of leaves and distribution may change from panel to panel within a sequence set.

Slip Match

Adjoining leaves are slipped out in sequence with all same-face sides exposed.

- The joint may not be noticeable if grain is straight

- Figure repeats, but grain does not match at joints.

- Produces a uniform color because all faces have a similar light reflection.

- A leaning effect may occur if the specie used does not demonstrate a straight grain.

Center Match

Each panel face is assembled of an even number width before edge trimming.

- There is a veneer joint in the center of the panel producing horizontal symmetry.

Architectural End Match

- Veneer is book matched end-to-end as well as side-to-side.

- Wood grain is continuous in length as well as width.

- Appropriate when panel height exceeds the veneer length.

Continuous End Match

- Multiple panels end matched for length using a single length of veneer.

- Made as a single panel for length and then cut apart.

Sequence Match

- All panels are uniform length.

- Architectural grade veneers are matched for color and all panels of the same size will have continuity of grain.

- Other size panels must be cut during installation which may interrupt grain continuity.

Panel Sizes

Panel sizes are 1/8″ – 2″, 4′ x 8′ up to 5′ x 12′

Long Grain and Cross Grain Counter Front Material (Correct Sanding with The Grain)

Core Options

The core options are MDF, Veneer Core, Particle Board, Fire Rated, Moisture Resistant, Formaldehyde Free and Marine & Exterior.

Available As

Running Book Matched, Balance Book Matched, Running Slip Matched, Center Balance Matched, Flitch Matched, Random Matched, End Matched, Sequenced & Numbered.

Edge Banding

7/8 & 13/16 Pre-Glued, 15/16 & 7/8 Non-Glued Automatic

Veneers

2-Ply Wood Backer, 10-mil, 20-mil , 30-mil Paperback, Phenolic Backer, Peel & Stick Adhesive Backer

Thick Face/Rough Sawn/Scratched Veneer & Recon Veneer

Special Machining

Cut to Size, Custom Finishing, UV Finished, UV Seal/Fill, Colors & Stains and Water Based Primer

Additional Information

- Numerous premium domestic, exotic, crotch, and burl veneers

- Architectural Plywood with your choice of veneer face, back & core

- Specialty cores available in various sizes (Fire Rated/Nauf/etc.)

- Ask about our FSC®-Certified Cores and Veneers

- Specializing in Cut to Size and Blue Print Matching

- Edge Banding

- Sketch Face Panels – Diamond, Reverse Diamond, Box, Starburst

- Matching & Many More

- Flexible Veneer Backers available – 10, 20, 30 Mil. paper, Polyback and 2-Ply (wood backer)

- Aggressive lead times and delivery on Most Products.